Glass tempering furnaces are essential in the production of tempered glass, a durable and high-strength material widely used in various industries. Understanding the working principles and key components of a glass tempering furnace can provide insight into the intricate process of processing glass. This blog delves into the operation, technologies, and benefits of these machines while incorporating critical features such as temperature control, heat control, and cooling blowers.

The Glass Tempering Process

A flat glass tempering furnace transforms ordinary glass into tempered glass through controlled heating and rapid cooling. This process creates compressive stress on the glass surface and tensile stress inside, making the material stronger and more resistant to impact and thermal shock.

1. Heating Phase

The process begins with loading flat or shaped glass into the furnace. Advanced glass tempering machines use precise heat control systems to raise the glass temperature to approximately 600-700°C (1,112-1,292°F). This is the softening point where the glass becomes malleable. For soft coated glass, the furnace ensures the coating remains intact during this stage.

2. Temperature Control

Modern control systems in the furnace play a vital role in maintaining uniform heat distribution. Achieving consistent temperature is critical to ensuring high-quality results. Inaccurate temperature control can lead to defects like warping or uneven strength distribution.

3. Rapid Cooling (Quenching)

After heating, the glass is quickly transferred to the cooling section. Here, high-velocity air from cooling blowers is directed onto the surface of the glass. This rapid cooling hardens the surface while keeping the inner layers hot and flexible. The resulting stress gradient gives the glass its tempered characteristics.

Key Features of Glass Tempering Furnaces

- Heat Control: Advanced furnaces use precision technology to regulate heating elements, ensuring optimal energy efficiency and product quality.

- Soft Coated Glass Capability: Specialized machines handle coated glass without compromising the coating integrity.

- Cooling Blowers: These are critical for achieving uniform cooling rates across the glass surface, a key factor in producing tempered glass with consistent strength.

- Control System: State-of-the-art systems monitor every step of the process, including temperature, timing, and air pressure, to deliver high-quality results.

- Flat Glass Tempering Furnace Design: These furnaces are specifically engineered for flat glass processing, catering to industries like automotive, construction, and household appliances.

Applications of Tempered Glass

Tempered glass produced in a glass tempering oven finds applications in architectural glass (windows and doors), automotive glass (windshields and sunroofs), and safety glass for furniture and electronics. Its strength and shatter-resistant properties make it a preferred material in various demanding environments.

Why Choose Advanced Glass Machinery?

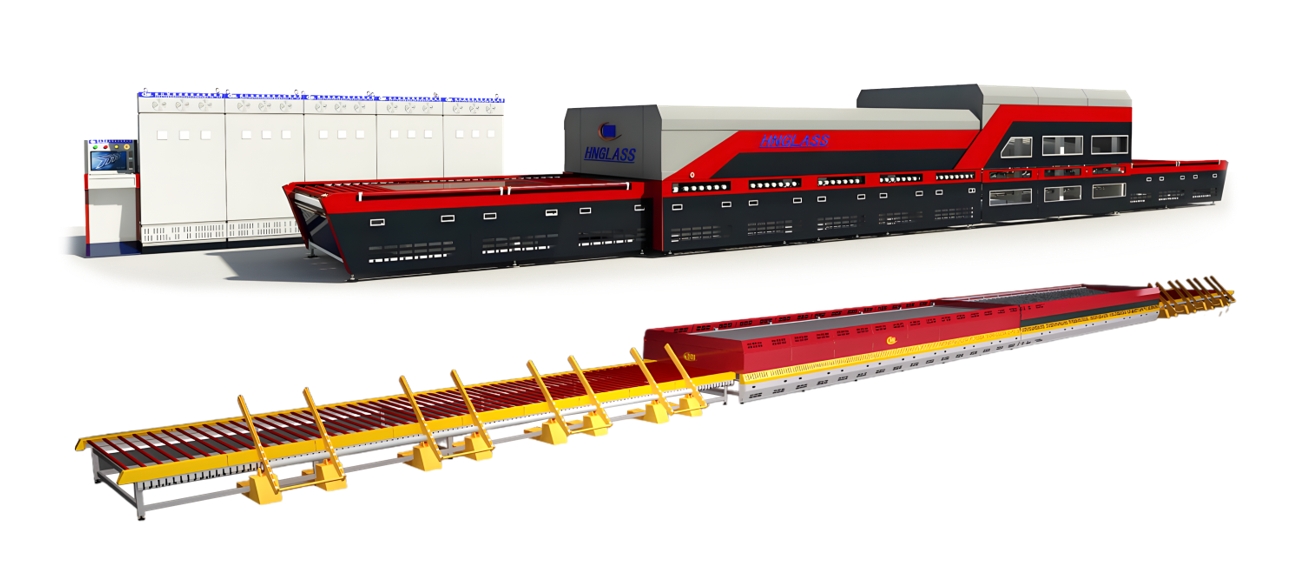

Modern glass tempering machines are equipped with the latest technologies to enhance productivity and quality. From flat glass tempering furnaces to multi-functional equipment, choosing reliable and efficient machinery ensures consistent performance and durability.

Conclusion

A glass tempering furnace is a cornerstone of the glass manufacturing industry, enabling the production of strong, safe, and versatile tempered glass. By leveraging advanced technologies such as precise temperature control, heat control, and innovative cooling blowers, these machines deliver high-quality products suitable for a wide range of applications. Understanding how these furnaces work highlights their critical role in processing glass and their value in modern manufacturing.

For more insights into glass machinery and innovations in the industry, explore our range of glass tempering ovens and solutions tailored to your needs.