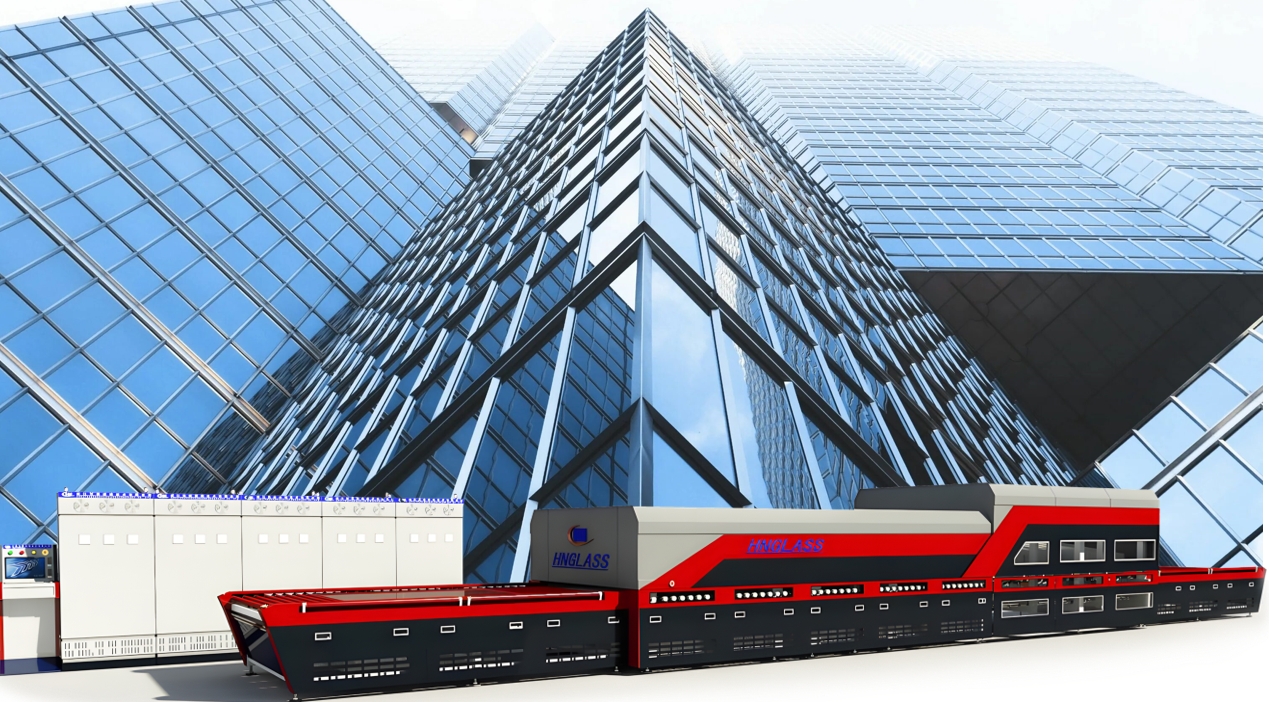

Home > News & Blog > What is Glass Tempering Furnace?

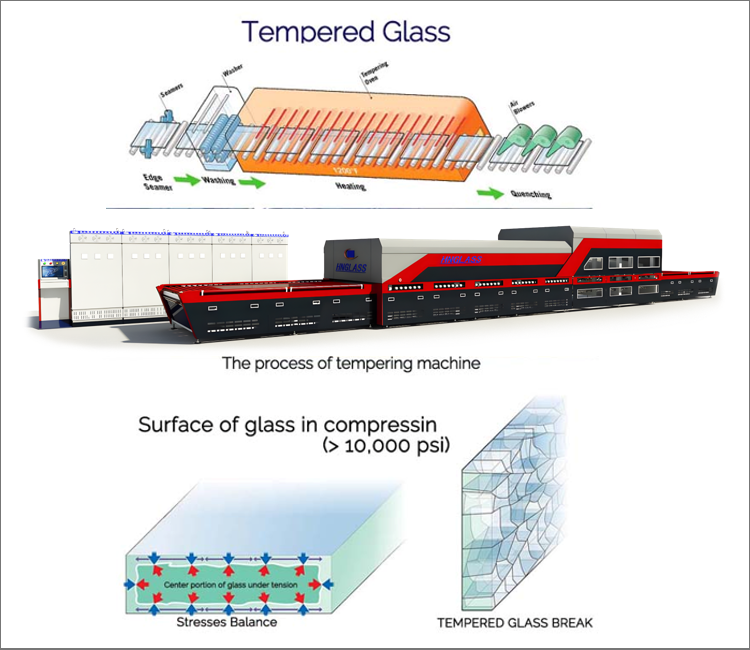

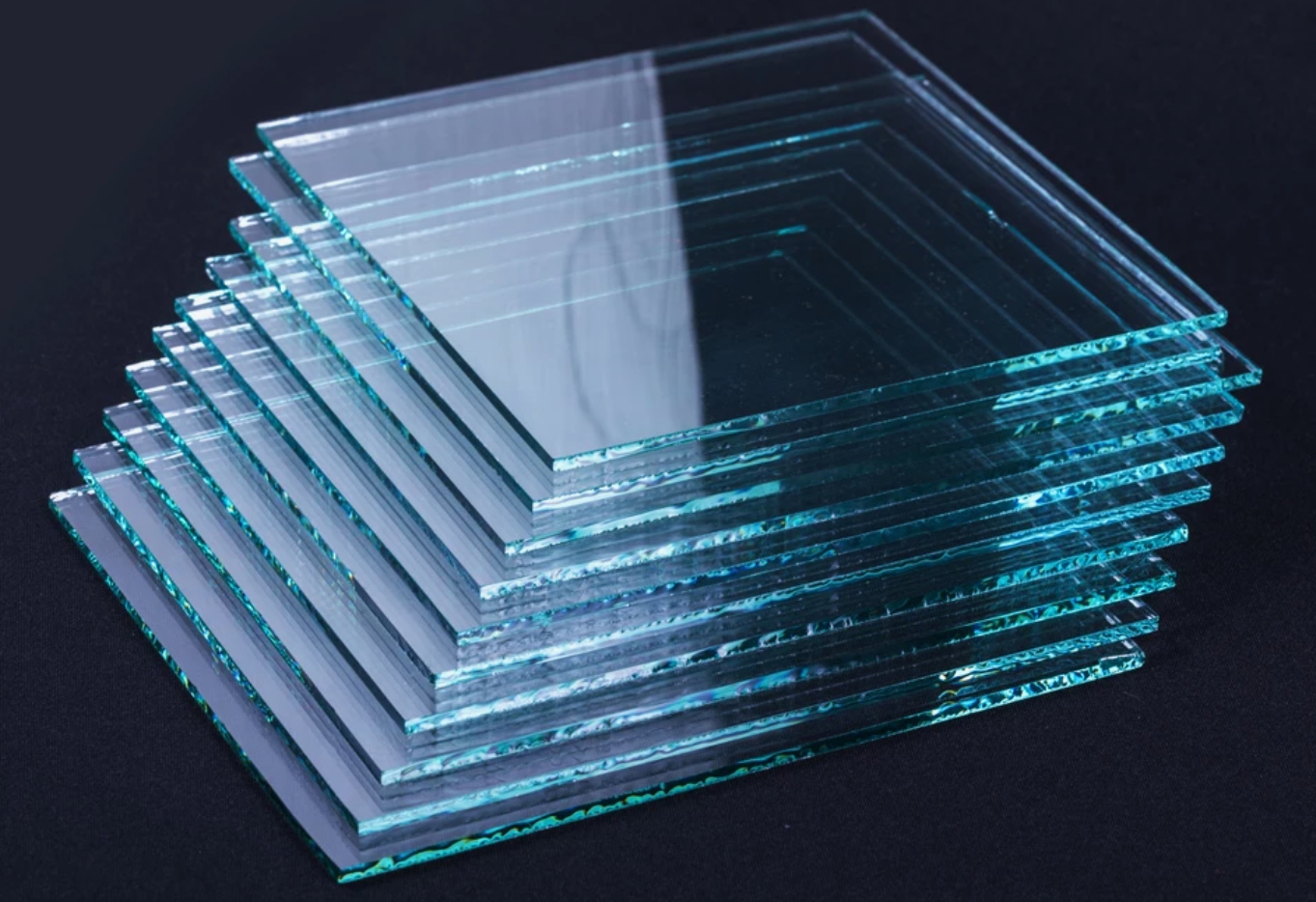

A glass tempering furnace is a specialized piece of equipment used in the glass processing industry to enhance the strength and durability of flat glass through a thermal treatment process. This process transforms ordinary annealed glass into tempered glass, a type of glass known for its increased resistance to impact and thermal stress. The tempering process involves heating flat glass to a high temperature and then rapidly cooling it, creating compressive stress on the surface and tensile stress within the glass.

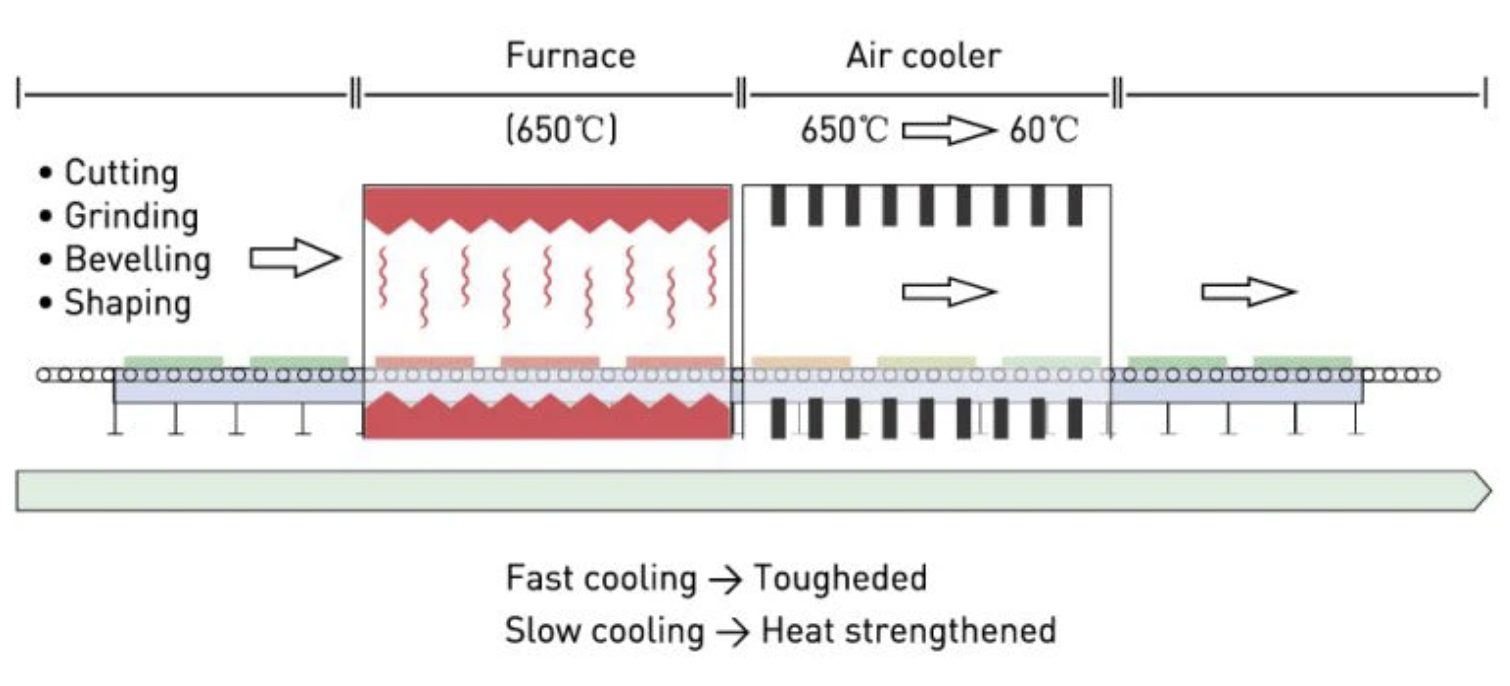

The tempering process in a glass tempering furnace begins by heating the glass to a temperature just below its melting point, typically around 620-650°C (1148-1202°F). Once the glass reaches the desired temperature, it is quickly transferred to a quenching section where it is rapidly cooled using high-pressure air jets. This rapid cooling, or quenching, locks in the stresses within the glass, making it much stronger than annealed glass.

Because this tempering method does not alter the chemical composition of the glass, it is referred to as a physical glass tempering process. The result is tempered glass, which is approximately four to five times stronger than untreated glass and is less likely to break into sharp, dangerous shards.

There are different types of glass tempering furnaces, each designed to accommodate various glass types and production needs:

1. Forced Convection Heating Tempering Furnace: This type uses forced convection to circulate hot air within the furnace, ensuring even heating of the glass. It is particularly effective for tempering glass with coatings, such as soft-coated (Low-E) glass, which requires more uniform heating to avoid damage to the coating.

2. Radiation Heating Tempering Furnace: In this type, the glass is heated primarily through radiation, where heat is transferred from heating elements to the glass surface. This method is suitable for standard glass types and is widely used for flat glass tempering.

Glass tempering furnaces are essential in producing various types of tempered glass used in multiple industries, including:

The tempering process is crucial for making heat-resistant and stronger glass that can withstand higher levels of stress, making it suitable for safety glass applications in construction, automotive, and other industries.

Modern glass tempering machines are equipped with advanced control systems that allow precise control over the heating and quenching processes, ensuring consistent quality in the tempered glass produced. These systems can be customized for different glass types and thicknesses, making them versatile tools in glass production.

The ongoing development in tempering furnace technology has led to improved energy efficiency, reduced environmental impact, and better control over the tempering process, making them integral to modern glass production.

A glass tempering furnace is a vital piece of equipment in the glass processing industry, transforming flat glass into tempered glass that is stronger and more resilient. With advancements in technology, these furnaces now offer greater efficiency, precision, and versatility, making them indispensable in producing high-quality glass products used in various applications.

Whether for architectural purposes, automotive industries, or specialized glass products, the role of the glass tempering furnace in glass production cannot be overstated. Understanding its operation and the different types available helps industry professionals choose the best furnace for their specific needs. As a leading manufacturer of glass tempering furnaces, we are more than happy to provide you with personalized advice. Feel free to send your inquiries to [email protected] at your convenience.